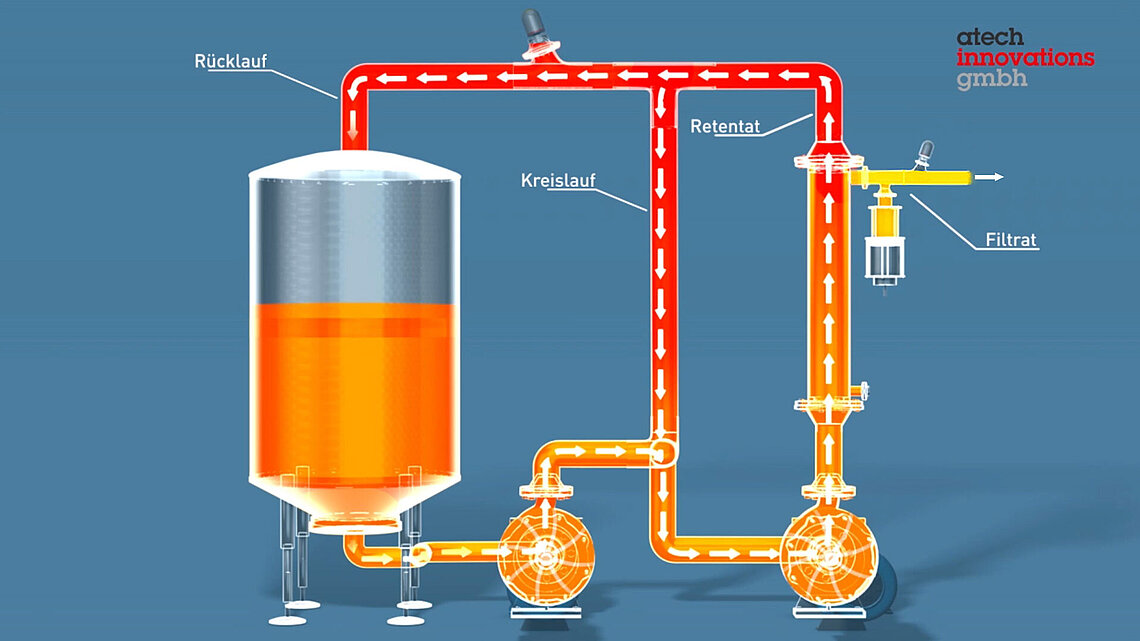

The principle of cross-flow filtration

In cross-flow filtration with ceramic membranes, the medium to be filtered flows through the channels of the membrane support. All particles larger than the pore diameter of the membrane are retained. Particles/molecules are enriched in the concentrate. The filtrate passes through the pores and - depending on the process combination - may pass through further stages in the process.

Perfectly suited for many applications: ceramic membrane filtration

“Simple” filtration with ceramic membranes is a mechanical separation method on a purely physical basis. During the process we almost exclusively use cross-flow filtration. As the name suggests, with this filtration method the feed flows parallel to the membrane and the filtrate is drawn off transversely to the direction of flow. Our ceramic multi-channel tubular membrane filters are designed for cross-flow filtration of liquids with high proportions of suspended solids, finest particles, oil, bacteria, viruses, etc., i.e. for both solid-liquid and liquid-liquid separation.

Cross-flow or tangential filtration

Simple filtration, for example with a sieve, is cake filtration in which the filtered particles remain on the filter medium as a layer. The layer becomes thicker and thicker until eventually, the filtrate can no longer pass the filter and it needs to be changed. Cross-flow filtration, also known as tangential filtration, is a filtration method in which the feed flow runs tangentially to the surface in the channels of the tubular membrane filter, so that retained particles and larger molecules do not accumulate on the membrane surface in the first place, and in contrast to cake filtration, no layer of all the filtered particles remains on the membranes. Nevertheless, in some applications a small cover layer may form, which can be removed very easily by backpulsing in ceramic membranes, so-called cross flow membranes.

Separation into two product streams

The liquid to be separated, the feed, is introduced under pressure at one end of the ceramic tube and flows through the channels until it exits at the other end. In this process, the fluid is divided into two product streams, respectively referred to as filtrate (which flows through the membrane) and retentate (which is retained by the membrane). The permeate flows through the porous structure of the membrane driven by the pressure, so that the entire permeate volume flow of all the individual channels of a ceramic tube is continuously discharged. The separated particles and molecules that are larger than the pores are removed from the permeate and these particles/molecules are built up in the retentate (concentrate).

The advantage of cross-flow filtration

A major advantage of cross-flow filtration is the better handling of liquids with a high solids content, as the retained particles are continuously removed from the surface of the ceramic membrane instead of remaining there as filter cake. This enables consistently high throughput rates. In addition to the “cleaning mechanism” of cross-flow filtration, the tubular membranes can be freed from any deposits on the filtration surface with a backflush or backpulse with permeate from the permeate side and the throughput rate can be kept consistently high.